LCA simulator

The road to a sustainable future always poses new challenges. Carbon neutrality is the most important and most urgent: achieving zero emissions by 2050 involves all businesses upfront. To significantly reduce the impact on the environment, companies are called on to continuously improve the production efficiency of their supply chain. This translates into benefits not only to the health of the planet, but also to the company itself.

For a reduced

environmental impact

A unique tool that through the definition of a data-driven improvement plan, makes it possible to better optimise the use of all resources used in the manufacturing processes.

This triggers a virtuous system that positively impacts the environment and production costs.

Creating

new manufacturing

processes

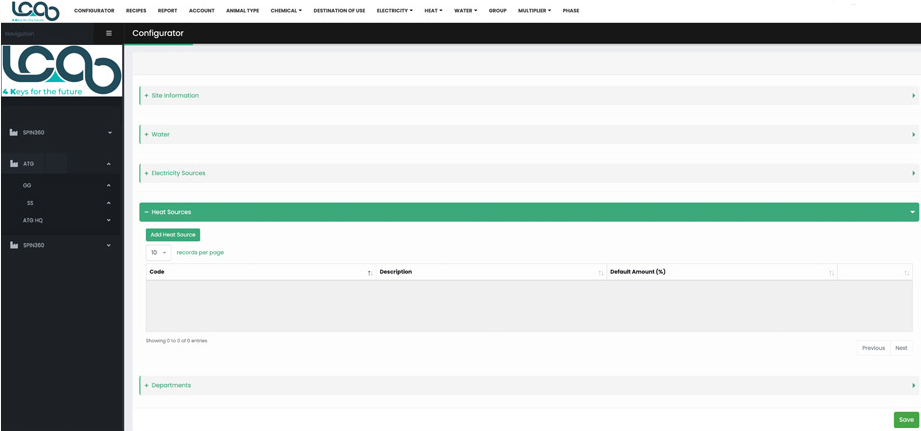

The tool acts as a full-on simulator of new production recipes. In the first step, the platform collects information about the manufacturing plant and the chemicals used in production (origin, quantities, characteristic).

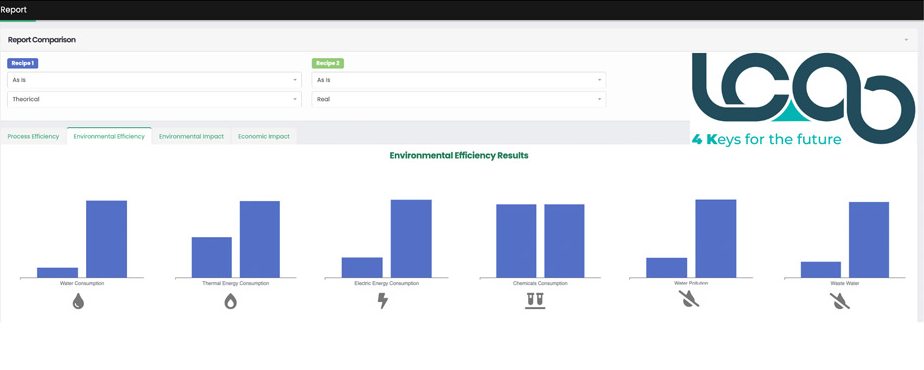

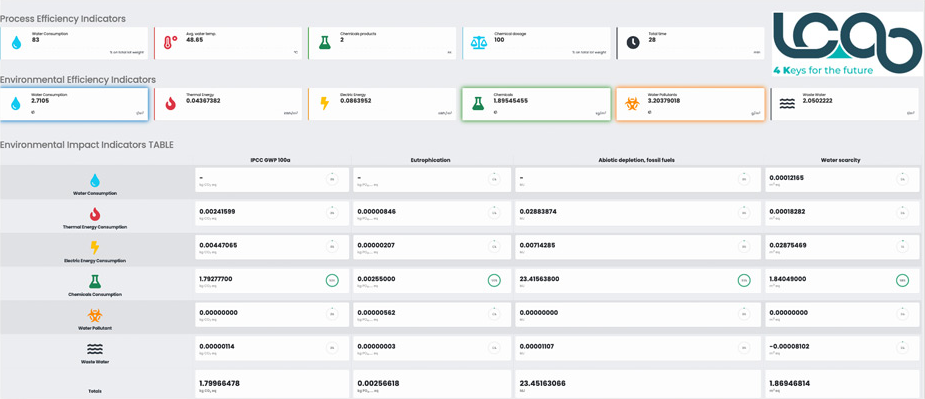

The data is then processed to provide one of the environmental indicators for the product. This is where the simulation phase starts. By modifying the parameters on environmental indicators, the tool makes it possible to formulate hypotheses that aim to improve the current production recipe.

Functionality

Current and future

applications

SPIN 360 LCA SIMULATOR fits most Drums control software and is 100% compatible with the SMART DRUM. The tool offers the ability to implement new features, databases, and modelling options, ranging from the tannery industry and its chemical suppliers to all batch process users.